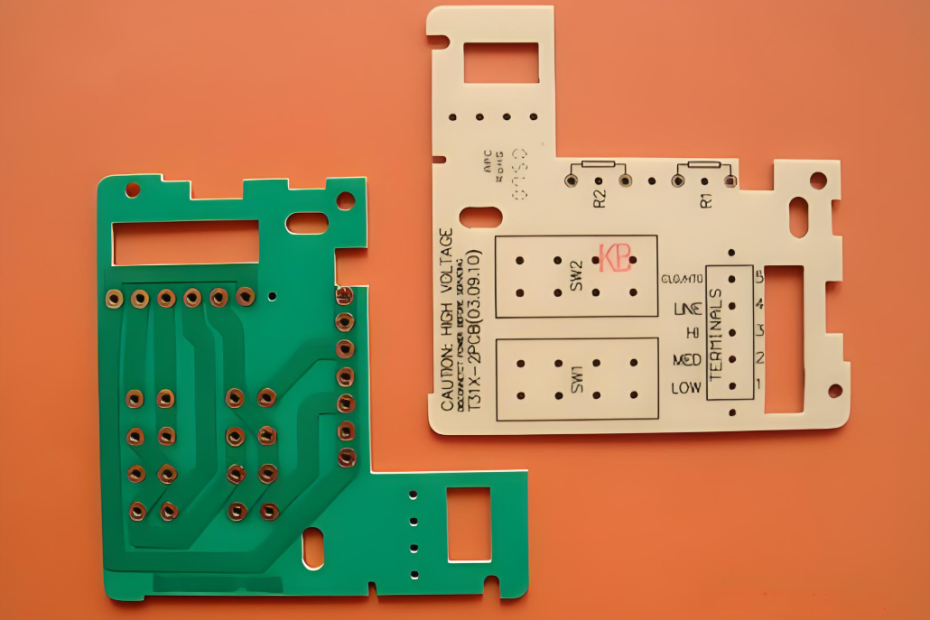

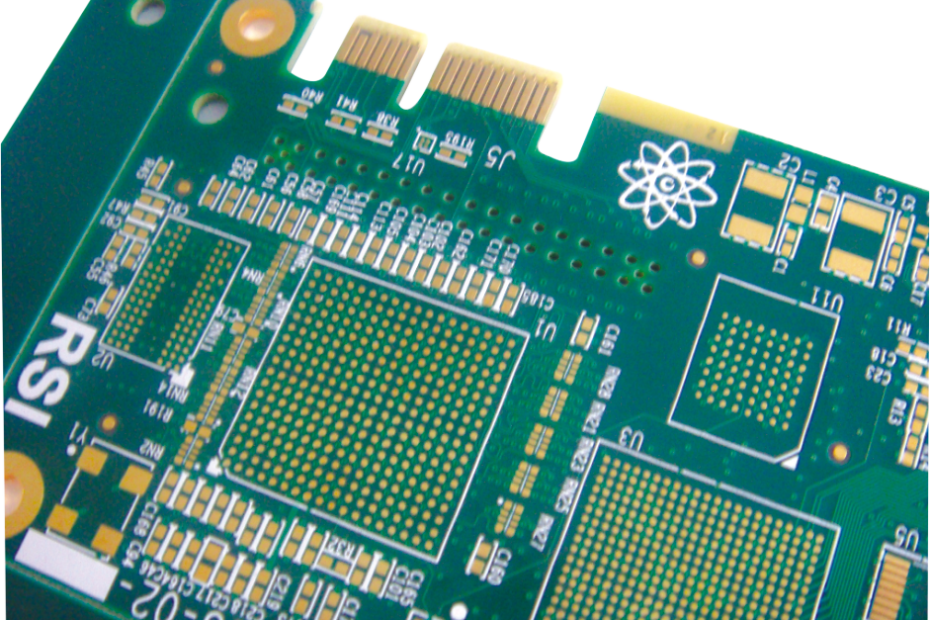

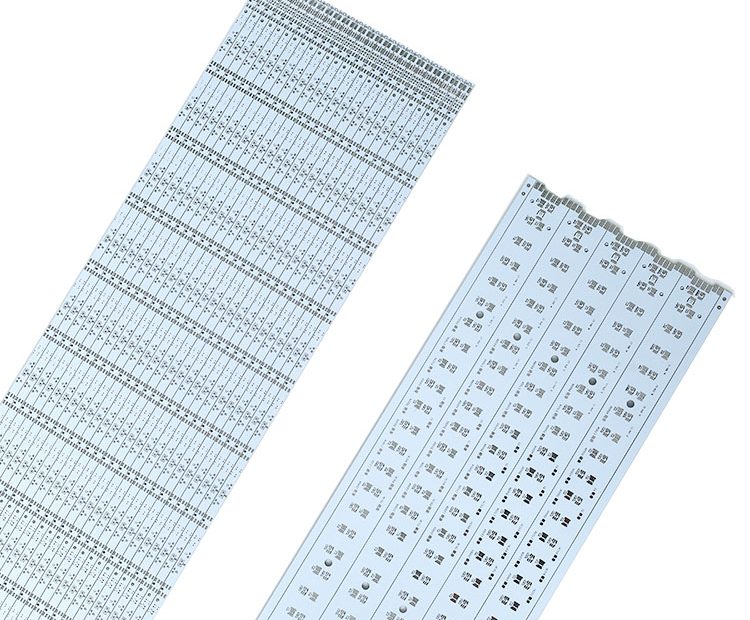

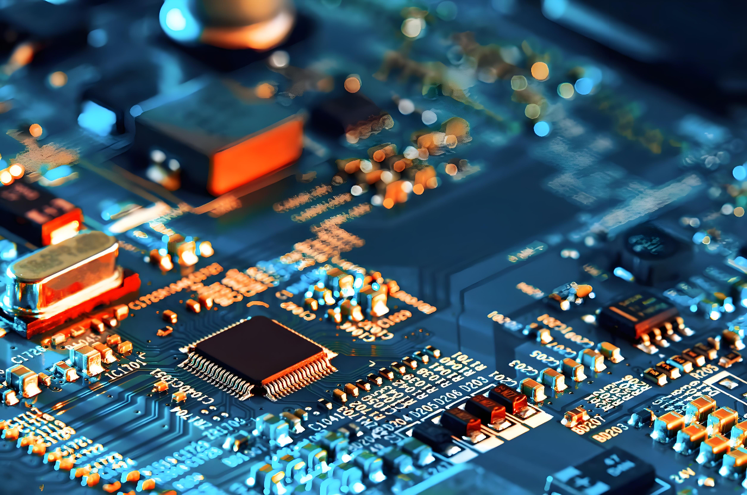

Medical Equipment PCBA

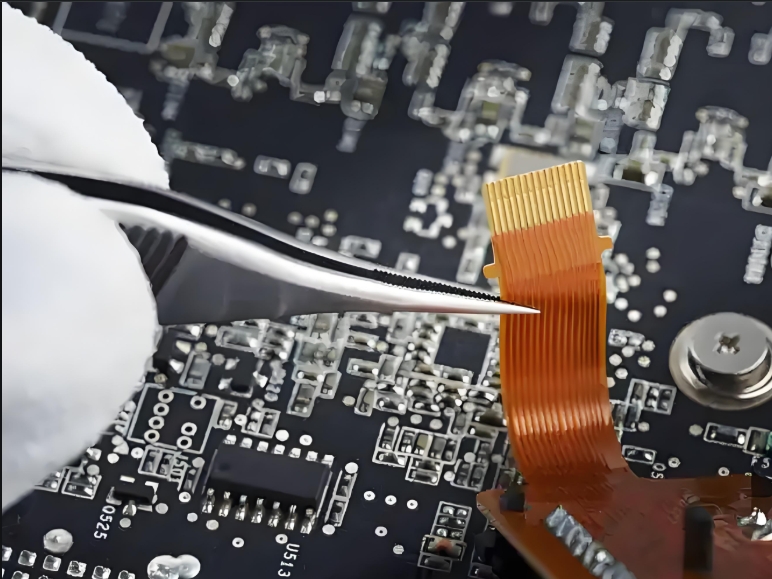

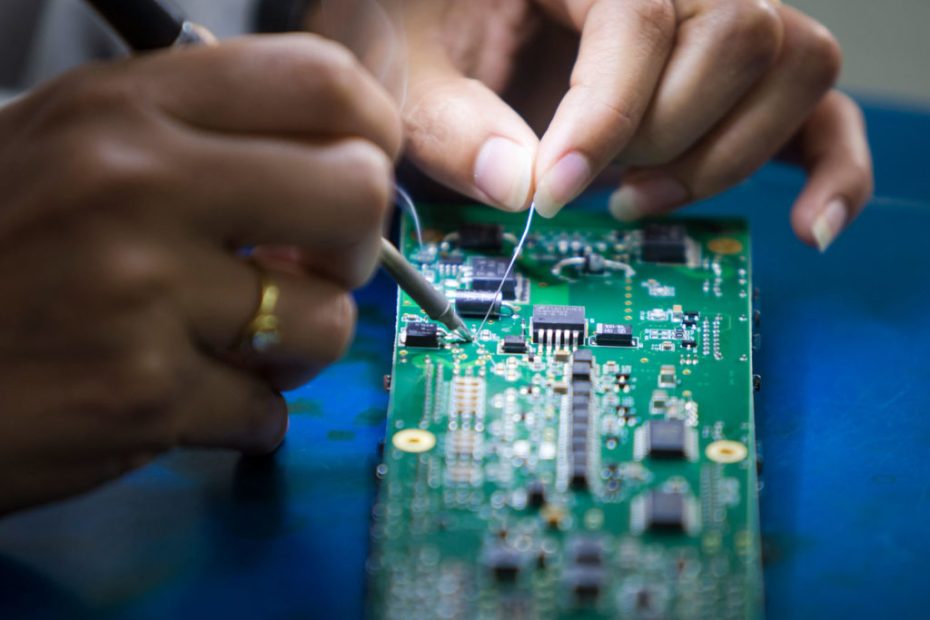

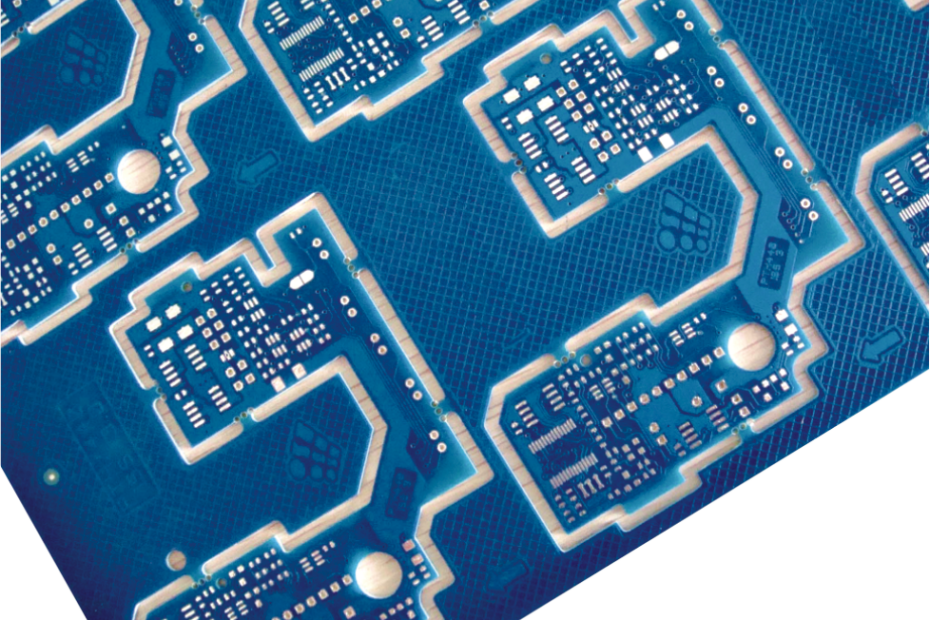

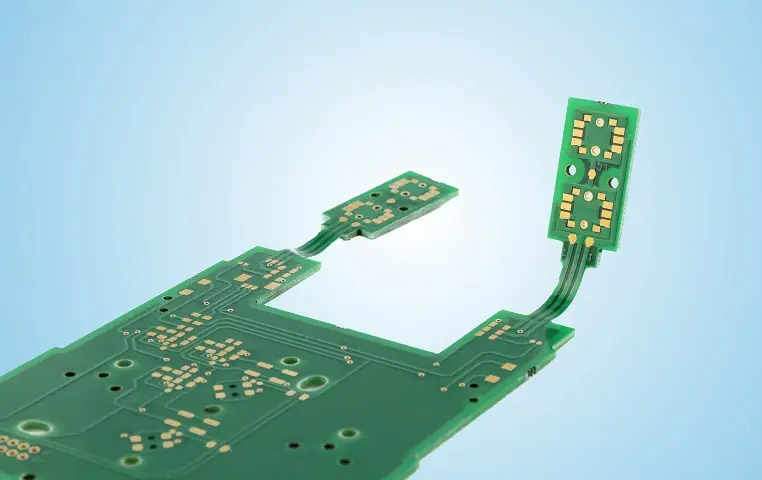

High Reliability & Longevity – Medical devices require uninterrupted operation, often in demanding environments. PCBAs are designed with robust materials and redundant circuitry to minimize failure risks. Strict Regulatory Compliance… Medical Equipment PCBA